Thread Milling vs. Thread Turning: Key Differences and When to Use Each

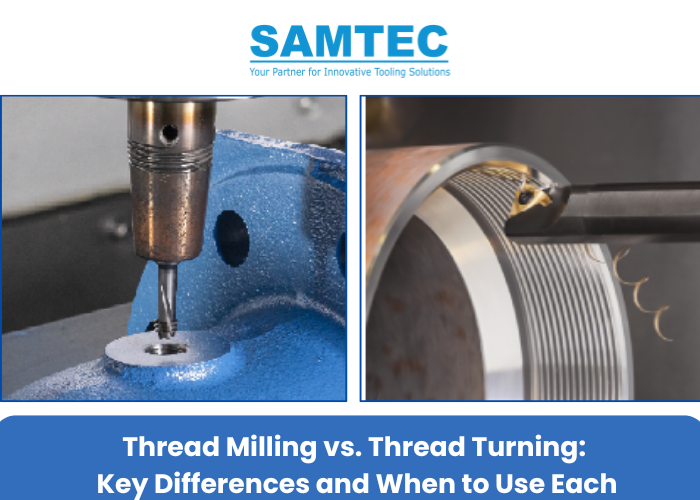

Threading is a crucial machining process for creating threads on various components, playing a pivotal role in industries such as automotive, aerospace, oil and gas, and medical devices. Among the most common threading methods are thread milling and thread turning. While both techniques achieve the same goal, they differ significantly in their approach, tools, and applications.

This blog delves into the key differences between thread milling and thread turning, their respective advantages, and guidance on selecting the right method for your application. Additionally, we highlight the high-quality tooling solutions available at Samtec Tools, a trusted provider of cutting tools and machining solutions.

What is Thread Turning?

Thread turning involves cutting threads on a cylindrical workpiece using a lathe. A thread turning tool moves along the rotating workpiece, gradually removing material to form the desired thread profile. This process is widely used for both internal (e.g., nuts) and external (e.g., bolts) threads.

Key Features of Thread Turning:

- Typically performed on lathes or CNC turning centers.

- Utilizes single-point cutting tools or indexable inserts.

- Suitable for high-speed production of standard threads.

What is Thread Milling?

Thread milling is a more modern approach that uses a rotating cutting tool to create threads. The tool moves in a helical path around the workpiece, generating threads through a subtractive process. Thread milling can be used for internal and external threads and is typically performed on CNC milling machines.

Key Features of Thread Milling:

- Uses thread mills, which are multi-tooth rotary cutting tools.

- Allows for the creation of threads in hard-to-machine materials.

- Supports customization of thread profiles and non-standard threads.

Thread Turning vs. Thread Milling: Key Differences

|

Aspect |

Thread Turning |

Thread Milling |

|

Machining Process |

Material is removed by a stationary tool moving linearly along the rotating workpiece. |

Material is removed by a rotating cutting tool moving along a helical path. |

|

Machine Requirements |

Requires a lathe or CNC turning center. |

Performed on a CNC milling machine or machining center. |

|

Tool Design |

Single-point tools or indexable inserts with specific profiles. |

Rotary thread mills with multiple cutting teeth. |

|

Accuracy and Versatility |

Suitable for standard threads with tight tolerances; limited customization options. |

Highly accurate and versatile, supports custom threads and non-standard profiles. |

|

Material Suitability |

Effective for softer and moderately hard materials. |

Suitable for hard-to-machine materials like hardened steel, titanium, and Inconel. |

|

Thread Quality |

Produces high-quality threads with excellent surface finish, especially in soft materials. |

Delivers superior thread quality for hard materials and complex profiles. |

|

Cycle Time |

Faster for high-volume production of standard threads. |

Slower due to its precision-oriented approach but ideal for custom threads. |

|

Application Focus |

Standard threading tasks in high-volume production. |

Complex, non-standard, or large-diameter threads. |

|

Cost Considerations |

More cost-effective for standard threading applications. |

Higher cost, but suitable for specialized applications requiring precision. |

|

Tool Life |

May have shorter tool life in harder materials. |

Longer tool life in hard materials due to advanced tool designs and coatings. |

Advantages of Thread Turning

- High-Speed Production: Ideal for mass production of standard threads.

- Cost-Effectiveness: Uses simpler tools, making it a more affordable option for standard threading tasks.

- Ease of Use: Thread turning is straightforward to set up and execute on a lathe.

Advantages of Thread Milling

- Custom Thread Profiles: Supports complex and non-standard thread geometries.

- Material Flexibility: Handles a broader range of materials, including hardened and exotic alloys.

- No Risk of Over-Tight Threads: Thread milling eliminates issues with tool deflection, ensuring accurate threads.

- Fewer Tool Changes: Multi-tooth thread mills can handle various thread sizes with the same tool.

Applications of Thread Turning

Thread turning is ideal for:

- High-volume production of standard threads.

- Applications requiring tight tolerances and high repeatability.

- Industries such as automotive and general engineering, where cost and speed are critical.

Applications of Thread Milling

Thread milling is best suited for:

- Custom thread profiles and non-standard pitches.

- Threads in hard or abrasive materials.

- Large-diameter threads or thin-walled components.

- Aerospace, oil and gas, and medical device manufacturing.

Choosing Between Thread Turning and Thread Milling

- Material Type

- Use thread turning for softer materials and high-volume production.

- Opt for thread milling for harder materials and challenging geometries.

- Thread Type and Profile

- Use thread turning for standard threads.

- Use thread milling for custom threads or multi-start threads.

- Machine Availability

- If your facility primarily uses lathes, thread turning is the logical choice.

- If you have CNC milling capabilities, thread milling offers greater versatility.

- Cost Considerations

- Thread turning is more cost-effective for standard applications.

- Thread milling justifies its higher cost for complex and high-precision tasks.

Tools for Thread Turning and Thread Milling: Why Choose Samtec Tools?

When it comes to high-quality tools for both thread turning and thread milling, Samtec Tools stands out as a leader in the industry. Here’s why:

- Comprehensive Product Range

Samtec Tools offers cutting-edge solutions for both thread turning and thread milling, catering to diverse industrial needs.

- Precision and Durability

All tools are engineered with precision and built from premium materials, ensuring long-lasting performance and reliability.

- Advanced Coating Technologies

Samtec Tools employs advanced coatings to enhance tool life, reduce friction, and improve surface finishes.

- Custom Solutions

For non-standard threads and specialized applications, Samtec Tools provides customized tooling solutions.

- Expert Support

Samtec Tools offers expert guidance on tool selection, setup, and optimization, ensuring you achieve the best results.

Real-World Scenarios: When to Use Thread Turning vs. Thread Milling

Scenario 1: High-Volume Production of Standard Bolts

- Method: Thread turning.

- Why: Faster cycle times and cost-efficiency make it ideal for mass production.

Scenario 2: Manufacturing Aerospace Components

- Method: Thread milling.

- Why: Handles exotic alloys and complex geometries with precision.

Scenario 3: Creating Large-Diameter Threads for Oil and Gas Applications

- Method: Thread milling.

- Why: Superior accuracy and the ability to produce large threads without tool deflection.

Scenario 4: Producing Small, Internal Threads for Medical Devices

- Method: Thread milling.

- Why: Ensures precision and high-quality finishes for intricate components.

Innovations in Thread Machining: The Role of CNC Machines

CNC technology has revolutionized both thread turning and thread milling by enhancing accuracy, repeatability, and efficiency. CNC lathes and milling machines allow for:

-

- Automated tool changes.

- Programming complex thread geometries.

- Achieving consistent results across large production runs.

Samtec Tools provides CNC-compatible tools designed to leverage the full potential of modern machining technologies.

Conclusion

Thread turning and thread milling are indispensable techniques in modern manufacturing, each with unique strengths and applications. While thread turning is ideal for high-speed, high-volume production of standard threads, thread milling excels in creating custom profiles, handling hard materials, and achieving unparalleled precision.

When choosing the right method, consider factors such as material type, thread geometry, production volume, and machine availability. For high-quality tools that deliver exceptional performance, explore the comprehensive range of solutions offered by Samtec Tools.

By selecting the right tools and machining method, you can optimize productivity, reduce costs, and achieve superior results in your threading operations.